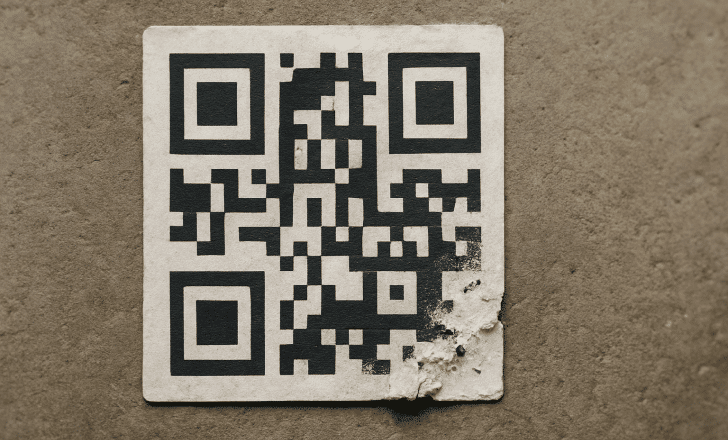

In a world where QR codes are part of nearly every marketing material—from product packaging to outdoor signage—ensuring they work under any condition is essential. But what happens when you print a QR code on textured surfaces like rough cardboard, fabric, metal, or plastic? That’s where things get tricky.

This article explores how to maintain the scannability and quality of your QR codes, even when printed on uneven or unconventional materials. Whether you’re running QR code campaigns on product labels or using dynamic QR codes on curved surfaces, we’ll help you avoid common mistakes and guide users to a successful scan every time.

Why textured surfaces challenge QR code scannability

Unlike smooth paper or digital screens, textured surfaces introduce variables that can hinder scanning. The QR code’s modules (the square pixels that store data) may be distorted, stretched, or broken apart depending on the surface material. Lighting conditions, reflections, and surface irregularities can further compromise readability.

In real-world scenarios, QR codes need to remain scannable on various devices and from different angles. This is especially true for outdoor signage, printed materials, or product packaging exposed to dirt, humidity, or movement.

So, how do you ensure reliable scanning across all these conditions?

The role of error correction in maintaining scannability

The good news is that QR codes are designed to be robust. Thanks to error correction, a QR code can remain readable even if up to 30% of its structure is damaged or unreadable. This makes it possible to scan codes that are scratched, slightly obscured, or distorted by uneven surfaces.

There are four standard error correction levels—L, M, Q, and H—ranging from low to high redundancy. If you’re printing QR codes on textured surfaces, a higher level of error correction (like Q or H) is often the safest choice. It increases the QR code’s resilience, allowing it to “fill in the blanks” when the pattern isn’t perfectly rendered.

However, higher error correction levels also increase data complexity, which means more modules, and therefore a larger size may be required to ensure clear printing.

QR code size matters—especially on textured materials

When it comes to printing QR codes on textured surfaces, size really does matter. The more data you encode—especially in dynamic QR codes or when using long URLs—the more complex the pattern becomes. That means you’ll need a larger code to preserve scanning distance and readability.

As a general rule, the minimum QR code size should be at least 2 x 2 cm for static uses and 3 x 3 cm or larger for dynamic or complex codes. But on uneven surfaces, it’s safer to go even bigger. The larger dimensions help counteract the effects of texture distortion, shadows, or reflective surfaces.

Also, consider the viewing distance. A QR code meant to be scanned from across a room—like on signage or large-format prints—needs to be proportionally larger than one on a small product label.

Printing QR codes on different materials: what to consider

Your QR code’s performance doesn’t just depend on the file—it also depends on print quality, color contrast, and how well the code stands out from its environment.

When you print QR codes on materials like kraft paper, wood, fabric, or metal, always test how ink or embossing interacts with the texture. Grainy or bumpy surfaces may interfere with the code’s readability. The quiet zone (a clear space around the QR code) is especially important here. Without it, the scanning device can’t identify where the code begins and ends.

To help ensure scannability:

- Use a high contrast between foreground and background. Black on white (or dark on light) works best.

- Avoid metallic or reflective inks that create glare under lighting.

- Maintain a clean, light-colored background if possible.

- Opt for vector formats (like SVG or EPS) for printing to preserve crisp edges.

A pixelated or blurry code—especially in raster formats—will struggle to survive the challenges of real world usage on textured or curved surfaces.

Dynamic QR codes vs static: which is better for rough surfaces?

Both static QR codes and dynamic QR codes can work on textured surfaces, but dynamic QR codes offer more flexibility. Since the destination URL can be changed without reprinting the code, you can fix a broken link or update content even after distribution. That’s essential for marketing materials where agility and accuracy matter.

Dynamic codes also allow you to track metrics like scan rates, locations, and devices used—insights that help you understand real-world performance. If you discover a particular printed batch underperforms, you can test and adjust your strategy.

Plus, with dynamic QR codes, you can use short URLs that minimize data encoded, allowing for simpler designs and smaller QR codes without compromising performance.

QR code design: balancing creativity and function

When creating QR codes for product packaging or outdoor campaigns, visual branding is often a priority. But it should never come at the cost of function. Some brands add logos or design elements into the QR code itself—but if you’re not careful, this can reduce the QR code’s scannability.

This is especially critical on textured surfaces where visual noise already presents a challenge.

To keep things balanced:

- Use a design-friendly QR code generator that offers customization without compromising the quiet zone or error correction.

- Test your design under real world conditions—low light, glare, angles, and motion.

- Always confirm that your QR code works across various devices before printing.

Your QR code should look good, but its primary goal is to guide users and generate engagement. A failed scan equals a lost lead.

Best practices for QR codes on textured surfaces

Printing on textures doesn’t have to be a gamble. Follow these tips to maximize the chances of a successful scan, even in challenging environments:

- Choose a high-quality QR code generator that supports dynamic codes and high-error correction.

- Use vector files to preserve detail during printing.

- Increase the size of the QR code based on texture and scanning distance.

- Ensure a generous quiet zone around the code, especially if the surface has patterns.

- Stick to high contrast color combinations and avoid gradients or shadows.

- Test with different devices under varied lighting to simulate real-world usage.

Testing is not optional—it’s how you discover and fix hidden issues before they impact your audience.

Real-world examples: where QR codes on textured surfaces succeed

You’ve likely seen QR codes on bottle labels, textured cardboard, or even embossed into leather. These aren’t theoretical applications—they’re now part of product packaging, promotional items, and industrial labels.

In wine marketing, for example, textured paper is often chosen for a premium feel. But unless the QR code has a proper quiet zone, high contrast, and generous size, scan rates will suffer. Similar issues arise with curved surfaces, like cans or tubes. The curve can warp the modules, so testing with real packaging before a full production run is crucial.

Brands running QR code campaigns in harsh environments—like outdoor festivals or construction sites—also need to account for dust, sun glare, and handling. High error correction levels and larger QR code sizes help mitigate those risks.

Using multiple QR codes in one environment

Sometimes you need to display multiple QR codes on a single surface—like a restaurant menu with separate codes for feedback, ordering, and social media. This increases the risk of confusion and scanning errors, especially if the codes are too close together or printed on an uneven surface.

To prevent this:

- Space codes apart and clearly label each one with clear instructions.

- Use icons or headings to guide users.

- Test that each code remains scannable individually and doesn’t trigger false positives.

In some cases, combining features into a single dynamic QR code with a menu or landing page can simplify the experience and improve results.

Why readability is everything in the QR world

No matter how creative or innovative your design is, none of it matters if people can’t scan your QR code. Every successful scan represents a potential conversion, lead, or insight. Every failed scan is a missed opportunity.

That’s why QRCodeKIT exists—to help businesses create QR codes that work beautifully in the real world, whether on sleek packaging or rough-textured materials. We understand the challenges of bringing a digital interaction into the physical environment, and we give you the tools to overcome them.

From generating high-quality codes to tracking performance, we help brands achieve seamless integration between print and digital—without compromise.

Final thoughts

Textured surfaces are part of the reality of modern packaging and print design. While they introduce complexity, they’re not an obstacle when you follow the right approach. By understanding how QR codes interact with surface materials, printing best practices, and design principles, you can make sure your code stands up to the demands of the real world.

Make every scan count—no matter the surface.