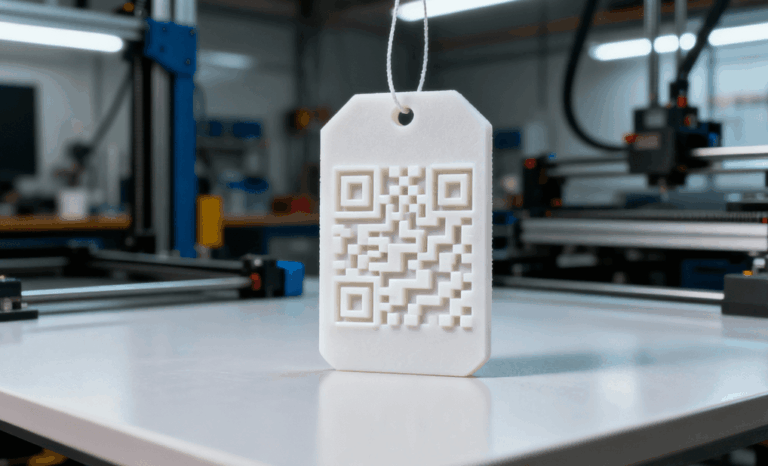

Creating a 3D printable QR code gives you a durable, customizable, and visually striking way to turn digital data into a physical object. Whether you need a QR code tag for a website URL, a Wi Fi password keychain, a functional product label, or a creative design element, transforming a standard QR into a 3D model makes the code long lasting and scannable even in challenging environments. With the right QR code generator, a clean STL file, and correct 3D printing settings, you can generate your own QR code and print it with sharper corners, strong contrast, and reliable readability. This guide walks you through the complete process so you can confidently create a high quality 3D printed QR that works every time.

What is a 3D printable QR code?

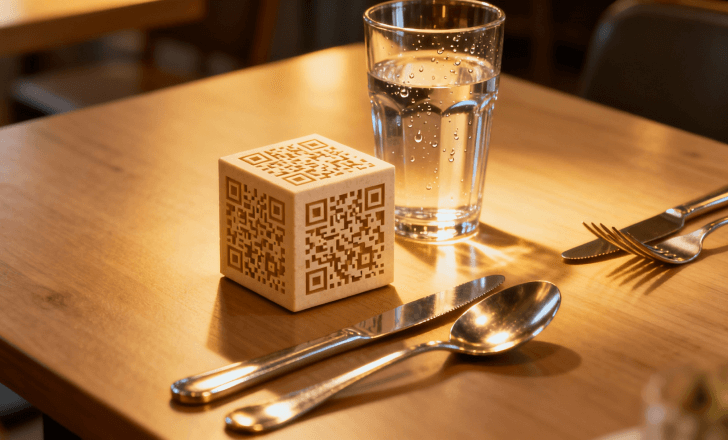

A 3D printable dynamic QR code is a three dimensional version of a standard QR pattern, exported as an STL file and prepared for 3D printing. Instead of relying on ink or a PNG image, the QR modules become raised or recessed geometry. Scanners detect the contrast created by shadows and depth, which replaces the typical black and white squares of a printed code. Because the shape is physical, a 3D printed QR is far more resistant to scratches, sunlight, water, and friction. It works perfectly for keychains, tags, signage, product identifiers, or embedded elements inside larger models. You can add holes, custom text, a frame, different colors, or multiple parts to create something both functional and visually unique.

How to generate your QR code before turning it into 3D geometry

To start, you need to create your QR code using a QR code generator capable of producing clean vector lines. This ensures that when you convert the file into 3D geometry, the modules maintain crisp edges and proper proportions. Begin by selecting your QR code type, whether it is a website URL, Wi Fi passwords, contact details, or any other QR code options supported by your tool. Once you enter the data and generate the code, download it preferably as an SVG file. An SVG preserves sharp lines better than a PNG image when imported into 3D software. If SVG is not available, choose the highest resolution PNG you can so the conversion process captures every module accurately.

What should you know about error correction for a 3D printable QR code?

Error correction ensures your 3D printed QR remains scannable even if the print has small imperfections. QR codes include built in redundancy so scanners can still read them when part of the pattern is dirty, worn, or slightly distorted. When creating a 3D printable QR code, selecting a higher error correction level gives you more safety. 3D printing introduces small artifacts on the top surface or between layers, so extra error correction helps compensate for them. When generating your SVG file, choose a level appropriate for your final use. Outdoor tags, textured surfaces, and objects that will be handled frequently benefit from higher redundancy.

How to convert your QR image into a 3D model

After generating your QR, the next step is to convert it into a 3D model. Import the SVG file into your preferred 3D modeling software. Many tools can extrude the 2D QR pattern automatically, turning each module into raised or recessed geometry. Adjust the height, thickness, and depth according to your needs. Make sure the modules stay uniform so scanners can detect the correct structure. If you want to embed the QR into another object, convert the pattern into a cutout, a stamp, or a relief. Then export the model as an STL file. This is the format your slicer will convert into G code, which becomes the print instructions for your machine.

Why does a 3D printed QR code need a perfectly flat surface?

A flat surface is essential for a printed QR code because scanning relies on clean contrast between light and shadow. Curved or slanted surfaces distort the spatial relationships of the modules, making the code unreadable. When preparing your STL file, ensure that the top surface is completely flat. If your object is curved, add a separate flat platform where the QR can be placed. Scanners depend on consistent height and sharp edges. Any uneven surface, warping, or irregular layer lines can interfere with readability. A perfectly flat top surface increases scanning reliability and produces sharper corners.

What customizations can you add to a 3D printed QR code?

A 3D printed QR code is highly customizable. You can add holes to create a keychain, include custom text for branding or labeling, add shaded backgrounds for contrast, or incorporate multiple parts so you can print in different colors. Some designers embed the QR into a tag or badge while others integrate it directly into a product. Adding a keychain hole is helpful for portable use, and printing in two colors, by pausing the printer at a specific layer, makes the contrast stronger. You can also increase thickness for durability, add a frame to help scanners align faster, or carve the QR directly into a larger model.

What slicing settings matter when preparing your 3D printable QR code?

Slicing your STL file properly is crucial to producing a scannable QR. Several settings determine whether your printed QR will be sharp enough for scanners. A fine layer height increases detail and improves corner accuracy. Slower print speeds help maintain clean edges. Thicker top layers produce a smoother top surface. Make sure extrusion width does not round off module corners. Over extrusion can blur the geometry, making the QR unreadable. If printing in multiple colors, insert pause commands at the appropriate layer. Review the G code preview to ensure each module remains distinct and does not merge with its neighbors.

How to ensure your 3D printing QR codes scan correctly

To test your design, preview the QR in your slicer and ensure that all modules are separated clearly. Before printing the final version, you can flatten the surface temporarily in your 3D tool and export a PNG to scan with your mobile device. If the first printed QR code does not scan, increase the depth of the raised areas, sharpen the edges, or re slice the model using different settings. Good lighting helps when testing, since shadows play a major role in readability. If needed, generate a new QR with higher error correction. Avoid sanding the modules because rounded edges make scanning more difficult.

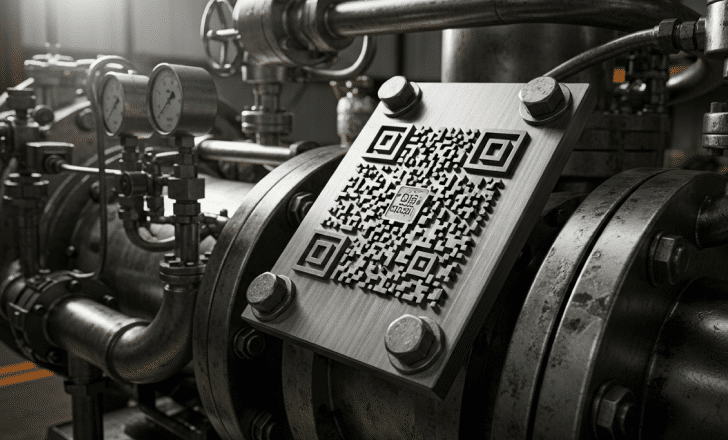

How to choose the right 3D printing materials for your QR code

Material selection affects durability and readability. PLA works well for indoor use and is easy to print. PETG offers superior strength and is resistant to sunlight and moisture. ABS, while harder to print, is ideal for industrial applications that require heat resistance. If you want to print outdoor signage, choose materials with good weather resistance. For improved contrast, print raised modules in a dark filament and the base in a light color. Avoid glossy filaments on the top surface because reflections reduce scanner accuracy.

What mistakes should you avoid when designing a 3D printable QR code?

Avoid shrinking the QR code too much because small modules do not print consistently. Do not use highly reflective materials. Do not distort the shape of the modules or alter the pattern. Never print the QR on a vertical surface because layer lines will cause distortion. Avoid excessive decoration that may interfere with scanning. Always prefer SVG over a low resolution PNG to ensure crisp geometry. And make sure your slicer does not smooth or automatically round corners.

How to embed your 3D printed QR code into other 3D projects

You can embed your 3D printed QR inside other models by importing both files into your 3D software and merging or subtracting the QR geometry. As long as the QR area remains flat and the modules stay uniform, scanners will read the embedded code easily. You can integrate QR codes into signs, equipment plates, product casings, or decorative objects. Export the final merged model as an STL file, slice it, and print it as a single piece or as multiple parts for color variation.

How durable is a 3D printed QR compared to sticker based codes?

A 3D printed QR code is significantly more durable than printed QR stickers. Stickers fade, peel, or get damaged over time. A 3D printed QR, made from materials like PETG or ABS, can last for years. As long as the raised or recessed modules maintain their shape, scanners will continue to detect the code accurately. For long term use, choose UV resistant materials and avoid printing extremely thin walls that may snap.

What file formats do you need to create a 3D printable QR code?

You will work with multiple file formats through the process. Start by generating your QR as an SVG file or a high resolution PNG image. Convert the vector shape into a 3D model and export it as an STL file. Load the STL into your slicer, which transforms it into G code. You can export previews as PNG images if you need to test, mail the file to collaborators, or store different versions for printing.

How to create your own QR code for 3D printing in seconds

The full process is straightforward. You simply select your QR code type, enter your URL or Wi Fi credentials, generate the code, download the SVG, convert it into a 3D model, export the STL, slice it, and print it. You can customize your QR by adding holes, frames, layers, backgrounds, or multiple colors. With the right software and settings, you can easily create unique 3D printed QR codes for personal, professional, or industrial use.