How QR codes are transforming supply chains

QR codes in supply chain management have gone from novelty to necessity. These compact, scannable squares are now driving real-time visibility, error reduction, and data-rich processes at every stage—from raw materials to final delivery.

Whether you’re managing warehouses, tracking shipments, or updating inventory records, incorporating QR codes is one of the most accessible ways to improve supply chain efficiency.

Why use QR codes in supply chain management?

QR codes offer high data capacity and easy readability, making them ideal for fast-paced logistics operations. Unlike traditional barcodes, QR codes store binary data, enabling them to hold detailed product information, batch numbers, expiration dates, and tracking IDs.

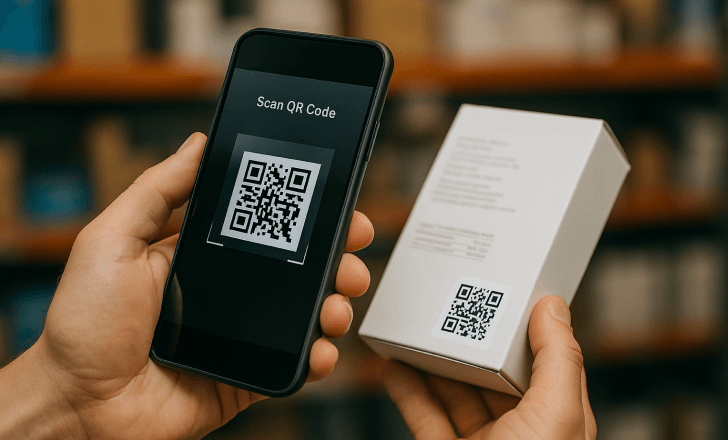

They can be printed on product packaging, labels, or containers, and scanned using mobile devices or scanners. This makes them perfect for improving supply chain visibility across complex supply chains.

How do QR codes work in a supply chain system?

A QR code scan connects to a database entry containing relevant data. For example, scanning a code on a pallet might reveal shipment contents, origin, destination, handling instructions, and real-time location updates.

Each scan updates inventory records or triggers workflow automations. Paired with inventory management software or a supply chain management system, QR codes enable seamless tracking, reporting, and coordination throughout the supply chain.

QR codes vs traditional barcodes in logistics

While barcodes are still widely used, QR codes offer multiple advantages. They have higher data capacity, allowing you to encode more information per scan. They are also easier to read—even at awkward angles or when partially damaged—and offer two-dimensional scanning that doesn’t require precise alignment. Importantly, dynamic QR codes allow destination data to be changed without reprinting.

This translates to faster scanning, richer data, and improved traceability in chain management.

Where to implement QR codes in supply chain processes

QR codes can be deployed at virtually every stage of the supply chain. In the raw materials stage, they help tag components at the source for early-stage tracking. During manufacturing, they can monitor parts, track batches, and streamline quality assurance. In warehouse management, they optimize receiving, picking, packing, and dispatch operations. Shipping and logistics benefit from real-time tracking for both individual packages and full shipments. At the retail level, QR codes support shelf management, restocking, and even marketing campaigns.

Improving inventory management with QR codes

Inventory control is one of the top use cases for QR codes. With QR code labels on products or shelves, staff can scan data directly into your inventory system. This eliminates manual data entry and significantly reduces human errors.

For example, when new stock arrives, scanning a QR code can automatically update inventory records and trigger notifications to reorder or reallocate stock.

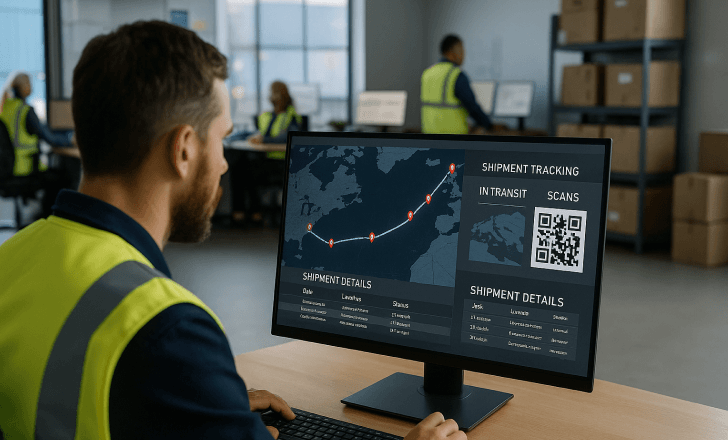

Enhancing supply chain tracking and visibility

QR code technology brings transparency to logistics operations. By scanning QR codes at key handoff points—from warehouse to shipping, distributor to retailer—supply chain teams gain instant access to real-time data.

This visibility improves coordination across suppliers, logistics partners, and internal departments, ultimately enabling better decision-making and more efficient responses to delays or disruptions.

Customizable QR codes for specific workflows

With a reliable QR code generator like QR Code KIT, you can create QR codes that adapt to your exact supply chain needs. Custom fields can include product specifications, storage requirements, quality control status, chain of custody data, and compliance documentation.

Customizable QR codes simplify internal processes while offering a standardized format for external partners.

Dynamic QR codes for real-time updates

One of the most powerful supply chain use cases is the ability to update information without changing the printed code. Dynamic QR codes let you redirect scans to new URLs or data points, add new tracking stages, or respond to recalls and regulatory changes.

This flexibility supports dynamic environments without adding cost to physical assets.

Using QR codes for asset management

QR codes are ideal for asset management software integrations. Tagging equipment, returnable containers, or reusable transport items enables lifecycle tracking, maintenance scheduling, and asset location management.

Because each unique QR code is scannable with mobile devices, field teams can update asset status instantly from any location.

Supporting quality control and assurance

QR codes make it easier to enforce and document quality standards. You can link a code to detailed information about inspection results, certification files, or checklists.

At each production or packaging stage, a quick QR code scan confirms whether quality steps have been followed, helping prevent costly compliance failures.

Reducing errors and increasing speed

When it comes to logistics processes, even small delays or inaccuracies compound into bigger issues. QR code usage helps reduce human errors by eliminating manual typing and verification steps.

For example, scanning QR codes during order picking, packing, and shipment creation minimizes delays and ensures accuracy, leading to greater operational efficiency.

Enabling real-time data capture with mobile devices

Thanks to the ubiquity of smartphones and tablets, scanning QR codes no longer requires expensive hardware. Mobile apps allow workers to scan and interact with QR code data from anywhere, even in remote locations.

This lowers onboarding costs and accelerates adoption across teams.

Integrating QR codes with inventory management software

The real power of QR codes in supply chain management lies in their integration with software tools. By linking QR scans with your inventory management system or supply chain software, you unlock real-time tracking of goods, automated updates across systems, and dashboards showing current inventory levels.

This integration makes your operation more agile and responsive.

Boosting warehouse management with QR code scans

Within the warehouse, QR codes play a key role in organizing and optimizing workflows. For instance, they can label storage zones and shelves, streamline product movement during putaway and retrieval, and verify outbound shipments.

This helps eliminate misplaced goods and speeds up day-to-day warehouse management tasks.

Tracking shipments more accurately

Tracking capabilities improve when you implement QR codes at key logistics stages. For example, attaching QR code labels to packages allows for scan-based tracking at each transit hub, while a final scan can log proof of delivery.

Customers and partners benefit from better visibility and fewer lost shipments.

QR codes on product packaging: Beyond marketing

While many associate QR codes on product packaging with marketing campaigns, they’re just as valuable for logistics. You can use packaging QR codes to track expiration dates, display storage instructions, link to digital product specifications, and enable returns or recalls.

This empowers direct customers to make more informed purchasing decisions while streamlining backend logistics.

Managing raw materials across locations

In industries with multiple sourcing points, QR codes simplify tracking raw materials across sites. Each batch can be tagged at origin, enabling full traceability, consistency across suppliers, and accountability in case of defects.

This is especially useful in food, pharmaceutical, and electronics manufacturing.

Supporting POS systems and replenishment

Retailers can use QR codes at point of sale (POS) to support inventory tracking and auto-replenishment. When items are scanned at checkout, inventory levels update automatically, triggering restocking workflows in your inventory system.

This bridges the gap between sales and supply chain in real time.

Ensuring data security with QR code platforms

Data security in QR code systems is essential, especially for sensitive supply chain data. QR Code KIT offers features like HTTPS links, expiring or password-protected codes, and scan tracking with access logs.

These features ensure that only authorized personnel can access or manage QR codes.

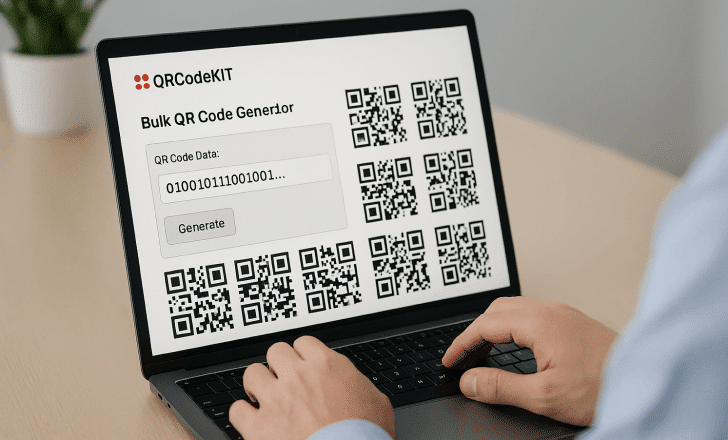

Managing customizable and dynamic codes at scale

Supply chains often deal with thousands of moving parts. With the right QR code generator, you can manage QR code creation, versioning, and analytics at scale.

QR Code KIT provides centralized management tools that allow you to create QR codes in bulk, organize by project or product line, update dynamic QR codes instantly, and monitor scan performance.

This simplifies operations across growing and distributed supply chains.

Compatibility with existing systems

Worried about disruption? Modern QR code platforms are designed to plug into existing systems. Whether you use legacy inventory tools or modern ERP software, QR Code KIT can adapt to your stack.

Integrations are available via API, allowing smooth connections with supply chain management software, asset management software, and warehouse platforms.

How to create QR codes for supply chain use

Getting started is simple. To create QR codes for your supply chain, choose a reliable QR code generator like QR Code KIT. Select the type of QR code (static or dynamic), customize the code with relevant fields, apply design options, and download labels for packaging, pallets, or documents.

You can also generate codes in bulk or use templates to speed up implementation.

Are QR codes the future of logistics?

In many ways, yes. QR codes are already proving more flexible and scalable than traditional barcodes. As supply chains grow more complex, businesses need tools that offer real-time updates, low implementation costs, and high adaptability.

Combined with AI, IoT, and blockchain, QR codes are positioned to play a central role in next-gen logistics operations.

What makes QR Code KIT ideal for supply chain applications?

QR Code KIT stands out thanks to its reliable and scalable QR code generation, support for dynamic and customizable codes, secure data handling, API integration with existing systems, and a user-friendly interface for non-technical teams.

From tracking shipments to enabling real-time inventory control, it’s the right QR code generator to improve supply chain efficiency at any scale.

What types of data can a supply chain QR code hold?

Depending on your needs, a QR code can include product names and SKUs, batch numbers, expiration dates, shipping instructions, compliance data, and URLs linking to live databases. Because QR codes store binary data, they can also point to external systems for even more detailed information.

Can QR codes improve supply chain sustainability?

Absolutely. By reducing paper records, minimizing shipment errors, and supporting circular logistics, QR codes contribute to lower waste, fewer returns, and smarter resource use.

They also support transparency initiatives that empower consumers to choose more sustainable products.

How to manage QR codes throughout the supply chain

Use a centralized dashboard to manage QR code usage across teams, regions, or suppliers. Assign access rights, monitor scan data, and update codes when needed. QR Code KIT makes it easy to track performance by code or product, audit usage for compliance, and collaborate with multiple stakeholders.

This helps you maintain control without sacrificing flexibility.

Final thoughts: QR codes are reshaping supply chains

From enhancing supply chain visibility to automating data capture, QR code technology is driving major improvements in logistics. By using customizable and dynamic QR codes, you can reduce errors, boost real-time coordination, and stay ahead in a competitive market.

It’s not just about replacing traditional barcodes. It’s about unlocking smarter supply chain management.